Interpretation of Linen Programs for Industrial Washing Machines

Large industrial washing machines are important production tools in laundry factories, mainly used for washing bed sheets, quilt covers, pillowcases and towels. However, many laundry plants may reduce the laundry steps or shorten the washing time. Although doing this once or twice may not reveal major problems, it will cause various issues in the long run, such as yellowing, hardening, and high PH value of the linen, etc. Each washing step of linen is significant.

A complete linen washing program often includes pre-wash, main wash, rinse, neutralization, and dehydration.

Pre-wash

During pre-washing, it is usually done at a high water level with normal temperature water for 1 to 3 minutes. Generally, no detergents are needed during pre-washing. Some laundry plants may omit pre-washing. This step cannot be omitted. The aim of pre-washing is to primarily remove some water-soluble stains, such as dirt on the surface of the linen. If there is no pre-washing, the dry fibers will absorb the direct addition of the detergents during the main wash. The detergents will deeply enter fibers and cannot be rinsed thoroughly during rinsing.

During neutralization, more neutralizing acid should be added to adjust the pH value of the linen. If washed in this way in the long term, linen will turn gray, yellow, and stiff due to the residual detergents in the fibers and dirt. It’s hard for the linen to return to its original texture. The cold water pre-wash is to let the water enter the fibers first. In this way, it will be easily rinsed thoroughly. After the pre-wash, the water drainage can be done directly.

Main wash

The main wash is the low-level heating washing. The addition of detergents during the main washing should be divided into two stages. In terms of washing bed sheets, duvet covers, and pillowcases, when the water temperature reaches 40℃, main wash detergents and alkaline solutions should be added. Then continue heating. When the water temperature reaches 75℃, add oxygen bleach and maintain this water temperature for 12 minutes of washing. For towels, oxygen bleach should be added and washed for 12 minutes when the water temperature reaches 80℃. Since oxygen bleaching can perform well at 70℃-90℃, the corresponding chemical materials should be added only after reaching a certain temperature.

· If the pure cotton is washed for a long time during the heated washing section, it will be prone to tearing, especially for those old linen which has a long service life and multiple washes. However, if the washing time is short, it won’t be cleaned thoroughly. As a result, the laundry principles should be followed. The water should be drained after the main wash and before the rinse.

Rinse

Rinse is generally a high water-level rinse at normal temperature. There is no need to add detergents. Each rinse time is 2 minutes. After the first rinse, the medium dehydration should be done to remove the main wash detergents and reduce residue.

Neutralization

Neutralization adopts a medium water level. Heat the water to 40℃-50℃ and then add the neutralizing acid. If the towels need to be neutralized, softeners should also be added to maintain the softness of the towels. Washing at this temperature for 3-4 minutes can restore the pH value of the towels and maintain softness.

High Dehydration

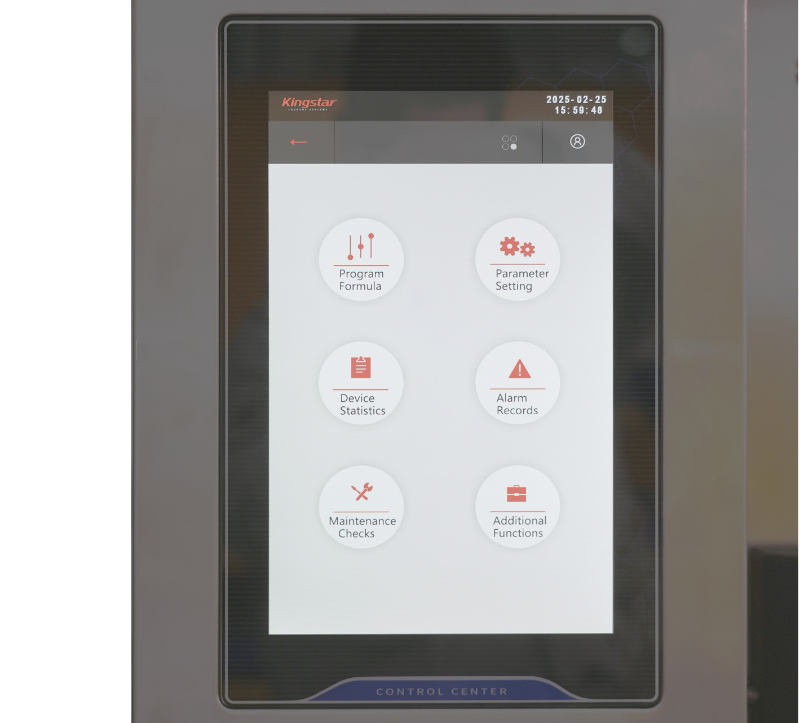

High dehydration can reduce the water content of the linen. The results of the high dehydration directly relate to the following time and steam consumption. If people use Kingstar 100kg industrial washing machines, the high spin speed can be set to 700rpm. The high dehydration time can be 5-8 minutes. If the high spin speed of your industrial washing machine cannot reach 700rpm, you can extend the dehydration time appropriately.

Conclusion

Above are the meanings of every step of industrial washing machines washing linen. Linen washing is a scientific and complete process. Every step has meaning. The parameters of every step have also been verified over time. Laundry plants should wash linen strictly according to the standard programs so that the linen can be good.

ADD:No.388 Xinggang Road, Chongchuan District, Nantong City, 226000, Jiangsu Province, China.

-

Phone: +86-13917089379

-

Tel:+86-13917089379

-

Fax:+86-0513-85663366

-

E-mail:[email protected]