Standard Washer 12/15/20/25kg

Kingstar Series washer extractors equipped with the world’s leading washing technology, Italian customized inner drum processing machine, using a large number of advanced manufacturing processes and imported components. Professional innovation and optimization design, a variety of personalized washing programs, which can easily complete the entire washing process with one click.

Compared with ordinary washing machines on the market, Kingstar washer extractor has more functions, higher configuration and higher degree of automation, and is especially suitable for professional laundries with more personalized requirements.

-

Laundry

-

Dry cleaner

-

Self-service

laundry

- 12kg

- 15kg

- 20kg

- 25kg

(86)+86-13917089379

-

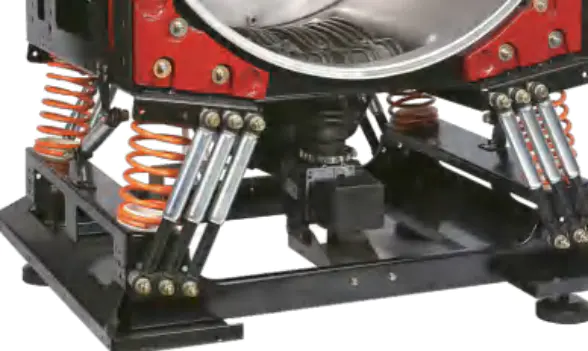

① Advanced Suspension and Shock Absorber System

Engineered with ultra-low vibration technology and equipped with German-branded dampers, the suspension system ensures stable and quiet operation on any type of flooring—without the need for a dedicated foundation. -

② 304 Stainless Steel Construction

The inner drum, outer cylinder, and all water-contact surfaces are constructed from high-grade 304 stainless steel, providing superior corrosion resistance, maintaining optimal washing quality, and minimizing the risk of mechanical failure or contamination. -

③ 10-Inch Full-Color HD LCD Touchscreen

The intuitive 10-inch full-color HD touchscreen supports both custom programming and one-touch operation, offering a simple, efficient, and user-friendly interface for operators at all skill levels. -

④ Electronic Door Lock System

The door is electronically controlled by software and remains locked until the high-speed extraction cycle is fully complete, effectively preventing accidental opening and ensuring operator safety. -

⑤ Intelligent Load Weighing System

Automatically detects the weight of each load and adjusts the water volume accordingly, significantly reducing heating and detergent consumption while maintaining consistent washing performance. -

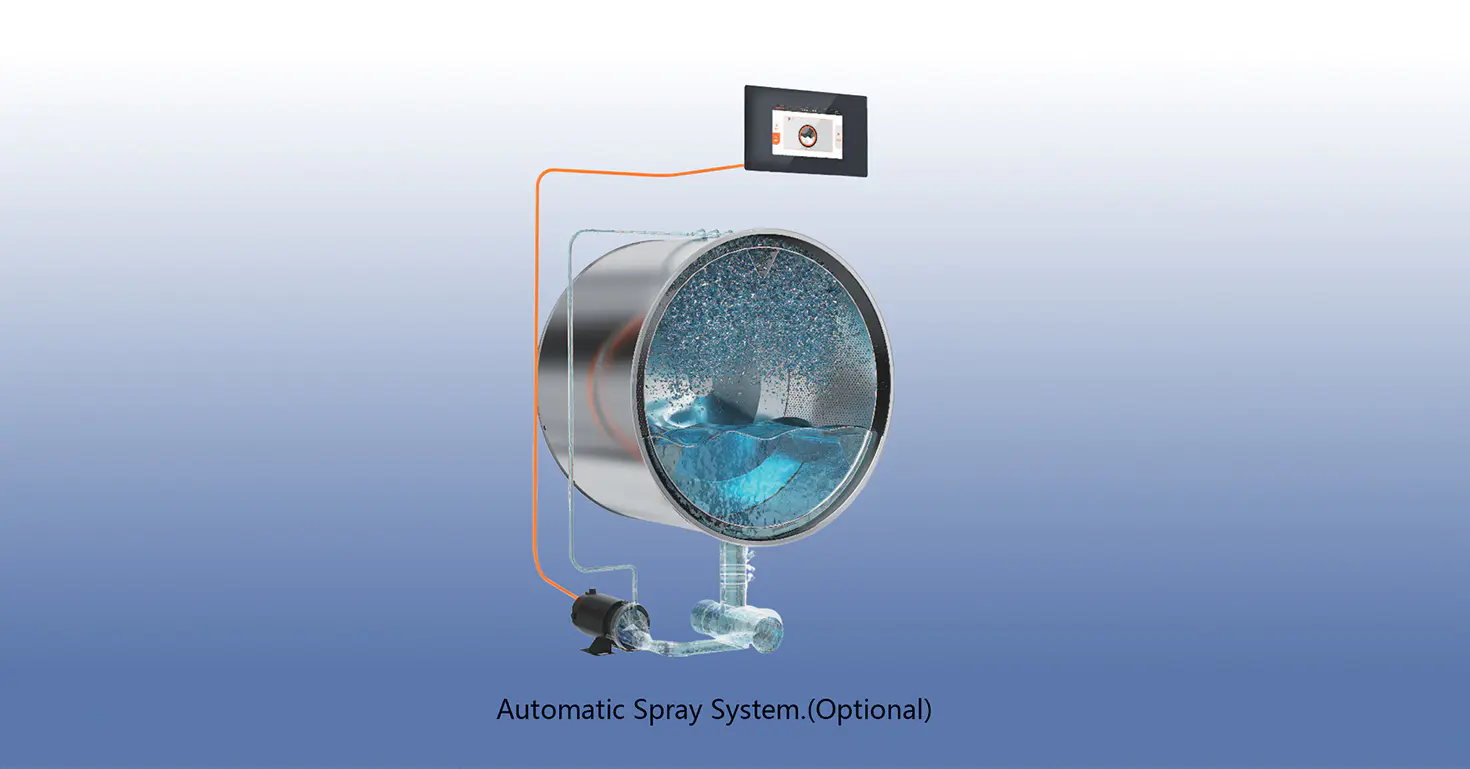

⑥ Optional Automatic Dosing System

Features an open-signal interface compatible with dispensers from any brand, enabling precise chemical dosing. This reduces chemical waste, minimizes manual intervention, and ensures more consistent and reliable washing results. -

⑦ High-Speed Extraction System

Equipped with a 300G extraction rate, the unit features a custom-built main motor from a publicly listed manufacturer, delivering superior extraction performance, significantly reducing drying time, and enhancing overall energy efficiency. -

⑧ Premium Imported Electrical Components

All electrical components are sourced from reputable international brands, including bearings supplied by TWB (USA), contactors from Schneider (France), and wiring and plugs from globally recognized manufacturers. -

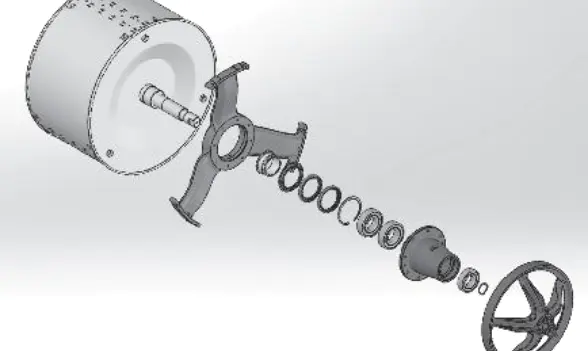

⑨ Three-Bearing Main Transmission

The main transmission adopts a high-strength, three-bearing design that ensures exceptional durability and enables up to 10 years of maintenance-free operation under normal working conditions. -

⑩ Long-Life Structural Design

The entire unit is engineered for a service life of up to 20 years and comes with a comprehensive 2-year warranty covering the whole machine.

-

Simple operation

Simple operation -

Intelligentize

Intelligentize -

Humanized design

Humanized design -

High quality

High quality

|

Specification Model |

SHS-2012 |

SHS-2015 |

SHS-2020 |

SHS-2025 |

|

Operating Voltage(V/P/Hz) |

380/3/50 |

380/3/50 |

380/3/50 |

380/3/50 |

|

Washing Capacity(kg) |

5~12 |

5~15 |

8~20 |

8~25 |

|

Drum Volume(L) |

120 |

150 |

200 |

200 |

|

Washing/Spinning Speed(rpm) |

30~850 |

30~850 |

30~850 |

30~850 |

|

Transmission Power(kw) |

1.5 |

1.5 |

2.2 |

3 |

|

Electrical Heating Power(kw) |

12 |

12 |

18 |

18 |

|

Noise(db) |

≤70 |

≤70 |

≤70 |

≤70 |

|

Extraction Factor(G) |

300 |

300 |

300 |

300 |

|

Automatic Dosing Ports (ways) |

9 |

9 |

9 |

9 |

|

Steam Pressure(MPa) |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

Inlet Water Pressure(Mpa) |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

Inlet Pipe Diameter(mm) |

DN20 |

DN20 |

DN20 |

DN20 |

|

Hot Water Pipe Diameter(mm) |

DN20 |

DN20 |

DN20 |

DN20 |

|

Drain Pipe Diameter(mm) |

Φ76 |

Φ76 |

Φ76 |

Φ76 |

|

Inner Drum Diameter ×Depth(mm) |

Φ650×372 |

Φ650×465 |

Φ750×410 |

Φ750×566 |

|

Overall Dimension (mm) |

890×885×1480 |

890×1070×1480 |

980×1050×1570 |

980×1160×1570 |

|

Total Weight(kg) |

400 |

420 |

480 |

500 |

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

2.Key Features and Innovations in 25kg Automatic Washer Extractors

3.The Impact of Automatic Washer Extractors on Commercial Laundry Operations

English

English русский

русский Español

Español Deutsch

Deutsch