Smart High-Speed Washer

Kingstar electric washer-extractor can be used in hotel laundry factories, hospital laundry factories, and laundromats. An electric washer extractor can process a large amount of linen at one time with a very high dehydration factor and high dehydration rate.

-

Laundry

-

Dry cleaner

-

Self-service

laundry

- 30kg

- 40kg

- 60kg

- 100kg

- 120kg

(86)+86-13917089379

-

① Leading Technology

(1)12.1-inch HD Touchscreen Design:

Kingstar fully automatic washer features a 12.1-inch HD touchscreen design, capable of automatic wate addition, prewash, main wash, rinsing, and neutralizing processes. It includes 30 preset wash programs and 5 frequently used one-touch automatic cycles.

(2)Intelligent Control System:

The intelligent weighing system in the Kingstar fully automatic washer precisely detects each load's weight and automatically adjusts the water, steam,and detergent levels accordingly. This ensures consistent wash quality while reducing consumption of water, electricity, and chemicals.

(3)Smart Three-Color Status Indicator:

The Kingstar fully automatic washer is equipped with a smart three-color status indicator, enabling clear visibility of the machine's operation from a distance. The indicator displays key statuses such as active cycle, cycle complete,and fault alerts. -

② Rational Structure

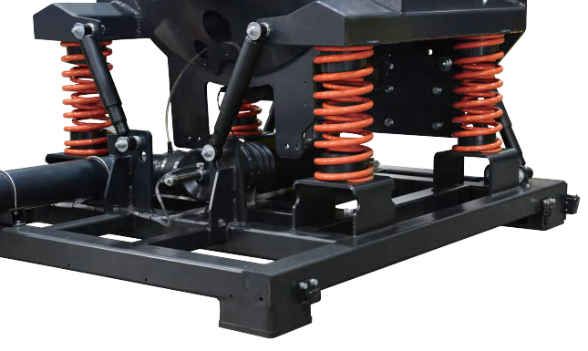

(1)Triple-Layer Shock Absorption System:

Kingstar's fully automatic washer adopts a unique lower suspension shock absorption system, featuring a triple-structure design: inner and outer dual-layer base springs, rubber feet,and dampers. This advanced system achieves ultra-low vibration with a shock absorption rate of up to 98%, eliminating the need for a fixed foundation and allowing installation on any type of floor.

(2)270-Degree Rolled Edge Drum Opening:

The Kingstar fully automatic washer features a 270-degree rolled edge at the junction between the inner and outer tubs. This precision-engineered design creates a smooth,high-strength interface with a minimal gap, significantly reducing the risk of fabric snagging or tearing during loading and unloading. -

③ Superior Dehydration Rate

(1)400G:

The Kingstar fully automatic washer is engineered with a reinforced structure, an efficient transmission system, and a high-quality inverter, all designed to support its powerful 400G extraction force. This high-speed extraction significantly reduces the moisture content in towels and linens, resulting in shorter drying times, higher daily throughput, and reduced steam consumption—substantially lowering operational costs.

④Safety Design

(1)Extra-Large Stainless Steel Loading Door:

The Kingstar fully automatic washer features a spacious, stainless steel front-loading door for fast and effortless garment handling. Its electronic lock system, controlled by advanced automation, opens only after the spin cycle completes, ensuring safety and peace of mind.

(2)304 Stainless Steel Components

All water-contacting parts—including the inner drum and outer cylinder—are made from durable 304 stainless steel. This construction offers superior rust resistance and consistent washing quality over years of use.

(3)3.5° Tilted Drum Design

The drum is tilted backward by 3.5°, enabling multidirectional garment movement for improved cleaning efficiency. This innovative design also helps prevent fabric damage near the door area. -

④ Safety Design

(1)Extra-Large Stainless Steel Loading Door:

The Kingstar fully automatic washer features a spacious, stainless steel front-loading door for fast and effortless garment handling. Its electronic lock system, controlled by advanced automation, opens only after the spin cycle completes, ensuring safety and peace of mind.

(2)304 Stainless Steel Components

All water-contacting parts—including the inner drum and outer cylinder—are made from durable 304 stainless steel. This construction offers superior rust resistance and consistent washing quality over years of use.

(3)3.5° Tilted Drum Design

The drum is tilted backward by 3.5°, enabling multidirectional garment movement for improved cleaning efficiency. This innovative design also helps prevent fabric damage near the door area. -

⑤ Branded Accessories

Imported Electrical components:

Kingstar fully automatic washer uses imported electrical components, including Mitsubishi inverters from Japan, Schneider contactors from France, and all wires, plugs, and bearings are imported brands. -

⑥ Precision-Processed Transmission Structure

(1)Reliable transmission system:

The transmission system of Kingstar fully automatic washer is meticulously designed, with the thickest diameter of the main shaft reaching 160 mm. Imported roller bearings and oil seals ensure no need for replacement for 5 years.

(2)One-Piece Die-Cast Belt Pulley:

The belt pulley of Kingstar fully automatic washer is made of high-grade aluminum alloy, integrally die-cast, ensuring the assembly accuracy of the main shaft, with excellent rust resistance, corrosion resistance, and shock absorption, making it durable and long-lasting.

-

Simple operation

Simple operation -

Intelligentize

Intelligentize -

Humanized design

Humanized design -

High quality

High quality

|

Specification Model |

SHS-2030 |

SHS-2040 |

SHS-2060 |

SHS-2100 |

SHS-2120 |

|

Operating Voltage(V/P/Hz) |

380/3/50 |

380/3/50 |

380/3/50 |

380/3/50 |

380/3/50 |

|

Maximum Washing Capacity(kg) |

30 |

40 |

60 |

100 |

120 |

|

Drum Volume(L) |

300 |

400 |

600 |

1000 |

1200 |

|

Maximum Spinning Speed(rpm) |

870 |

833 |

760 |

745 |

745 |

|

Transmission Power(kw) |

4 |

5.5 |

7.5 |

11 |

11 |

|

Steam Pressure(MPa) |

0.4~0.6 |

0.4~0.6 |

0.4~0.6 |

0.4~0.6 |

0.4~0.6 |

|

Inlet Water Pressure(Mpa) |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

0.2~0.4 |

|

Noise(db) |

≤70 |

≤70 |

≤70 |

≤70 |

≤70 |

|

Dehydration Factor(G) |

350 |

350 |

350 |

400 |

400 |

|

Steam Pipi Diameter(mm) |

DN25 |

DN25 |

DN25 |

DN25 |

DN25 |

|

Inlet Pipe Diameter(mm) |

DN40 |

DN40 |

DN40 |

DN50 |

DN50 |

|

Hot Water Pipe Diameter(mm) |

DN40 |

DN40 |

DN40 |

DN50 |

DN50 |

|

Drain Pipe Diameter(mm) |

DN65 |

DN100 |

DN100 |

DN100 |

DN100 |

|

Inner Drum Diameter ×Depth(mm) |

Φ820 |

Φ900 |

Φ1080 |

Φ1310 |

Φ1310 |

|

Inner Drum Depth(mm) |

570 |

660 |

680 |

750 |

970 |

|

Total Weight(kg) |

1350 |

2200 |

2600 |

3260 |

3360 |

|

Overall Dimensions L×W×H(mm) |

1245×1480×1770 |

1360×1690×1850 |

1540×1710×2025 |

1815×2090×2390 |

1815×2310×2390 |

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

2.Features and Benefits of Industrial Heavy Duty Washer Extractors

3.Considerations for Selecting Industrial Heavy Duty Washer Extractors

English

English русский

русский Español

Español Deutsch

Deutsch