Industrial Forward Tilting Washer

The design of large-diameter water inlet, automatic feeding system and optional double drainage can help you shorten the washing time, improve the efficiency and reduce the cost.

The inner and outer drums of the machine and the parts in contact with water are all made ofSUS304 stainless steel to ensure that the washing machine will never rust, and there will be no washing quality accidents caused by the rusting of the washing machine.

The linen feeding port of this machine is processed by a special machine. The mouth surface at the junction of the inner drum and the outer drum is all designed with a crimping mouth with 270degrees, surface is smooth, strength is high and the gap is small, so as to avoid the damage of linen.

The machine adopts down suspended shock absorption design, inner and outer double -layer seat springs+rubber shock absorption springs and machine feet rubber shock absorption and four damping shock absorption structure design,ultra -low vibration, shock absorption rate can reach 98% , Without ground base, can be used on any floor.

-

Laundry

-

Dry cleaner

-

Self-service

laundry

- 100kg

- 120kg

(86)+86-13917089379

-

①Front Tilt

(1)Reducing Worker Labor Intensity:

The Kingstar fully automatic washer incorporates a 15-degree forward-tilting design, which facilitates easier unloading of laundry and reduces manual handling for operators. -

②Leading Technology

(1)12.1-Inch HD Touchscreen Control Panel:

The Kingstar fully automatic washer is equipped with a 12.1-inch HD touchscreen for intuitive operation. The system supports automatic water filling,pre-wash, main wash, rinsing, and neutralization processes. It offers 30 preset washing programs and 5 frequently used programs for daily operations.

(2)Smart Load Sensing System:

The washer is equipped with an intelligent weighing system that automatically detects the weight of each load. Based on the measured load, the system precisely adjusts water, steam, and detergent levels, ensuring consistent washing quality while significantly reducing water, electricity, steam, and chemical consumption.

(3)Intelligent Three-Color Status Indicator:

The Kingstar washer incorporates an intelligent three-color LED status indica- tor, allowing operators to easily monitor machine status from a distance.The light colors indicate key conditions: Green for normal operation, Blue for cycle complete, and Red for fault or alarm status. -

③Rational Structure

(1)Triple Shock Absorption Structure

Kingstar's fully automatic washer adopts a unique lower suspension shock absorption system, featuring a triple-structure design: inner and outer dual-layer base springs, rubber feet, and dampers. This advanced system achieves ultra-low vibration with a shock absorption rate of up to 98%, eliminating the need for a fixed foundation and allowing installation on any type of floor.

(2)270° Rolled-Edge Opening Design

The Kingstar fully automatic washer features a 270-degree rolled-edge opening at the junction between the inner drum and outer cylinder. This design provides a smooth surface, enhanced structural strength, and minimal gap, which together reduce wear and prevent damage to garments during loading and unloading. -

④ Superior Extraction Performance

(1)Ultra-High Spin Extraction Power

The Kingstar fully automatic washer is engineered with a reinforced structure, an efficient transmission system, and a high-quality inverter, all designed to support its powerful 400G extraction force. This high-speed extraction significantly reduces the moisture content in towels and linens, resulting in shorter drying times, higher daily throughput, and reduced steam consumption—substantially lowering operationa costs. -

⑤ Safety Design

(1)Extra-Large Stainless Steel Loading Door

The Kingstar fully automatic washer features a spacious, stainless steel front-loading door for fast and effortless garment handling.Its electronic lock system, controlled by advanced automation, opens only after the spin cycle completes, ensuring safety and peace of mind.

(2)304 Stainless Steel Components

All water-contacting parts—including the inner drum and outer cylinder—are made from durable 304 stainless steel. This construction offers superior rust resistance and consistent washing quality over years of use

(3)3.5°Tilted Drum Design

The drum is tilted backward by 3.5°, enabling multidirectional garment movement for improved cleaning efficiency. This innovative design also helps prevent fabric damage near the door area. -

⑥ Branded Accessories

(1)Premium Imported Electrical Components

The Kingstar fully automatic washer is equipped with high-quality electrical components sourced from internationally renowned brands.

It features Mitsubishi inverters from Japan, Schneider contactors from France, and electrical wiring, plugs, and bearings from leading global manufacturers.

These premium components ensure reliable performance, extended service life, and stable operation in demanding industrial environments. -

⑦ Prescision-Processed Transmission Structure

(1)Precision-Engineered Transmission System

Kingstar's fully automatic washer features a robust,precision-engineered transmission system. The main shaftwith a maximum diameter of 160 mm, is supported by imported roller bearings and oil seals that offer stable, maintenance-free operation for up to 5 years.

(2)Die-Cast Aluminum Pulley for Superior Stability

The belt pulley is integrally die-cast from high-grade aluminum alloy to ensure precise shaft alignment. Its one-piece design provides excellent corrosion resistance, shock absorption, and long-term durability, contribut-ing to smooth,vibration-free operation.

-

Simple operation

Simple operation -

Intelligentize

Intelligentize -

Humanized design

Humanized design -

High quality

High quality

|

Specification Model |

SHS-2100T |

SHS-2120T |

|

Operating Voltage(V/P/Hz) |

380/3/50 |

380/3/50 |

|

Washing Capacity(kg) |

100 |

120 |

|

Drum Volume(L) |

1000 |

1200 |

|

Spinning Speed(rpm) |

745 |

745 |

|

Transmission Power(kw) |

11 |

11 |

|

Steam Pressure(MPa) |

0.4~0.6 |

0.4~0.6 |

|

Inlet Water Pressure(Mpa) |

0.2~0.4 |

0.2~0.4 |

|

Noise(db) |

≤70 |

≤70 |

|

Dehydration Factor(G) |

400 |

400 |

|

Steam Pipi Diameter(mm) |

DN25 |

DN25 |

|

Inlet Pipe Diameter(mm) |

DN50 |

DN50 |

|

Hot Water Pipe Diameter(mm) |

DN50 |

DN50 |

|

Drain Pipe Diameter(mm) |

DN100 |

DN100 |

|

Inner Drum Diameter(mm) |

Φ1310 |

Φ1310 |

|

Inner Drum Depth(mm) |

750 |

950 |

|

Front Tilting Angle(°) |

15 |

15 |

|

Total Weight(kg) |

3690 |

3830 |

|

Overall Dimensions L×W×H(mm) |

1860×1870×2470 |

1860×2090×2470 |

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

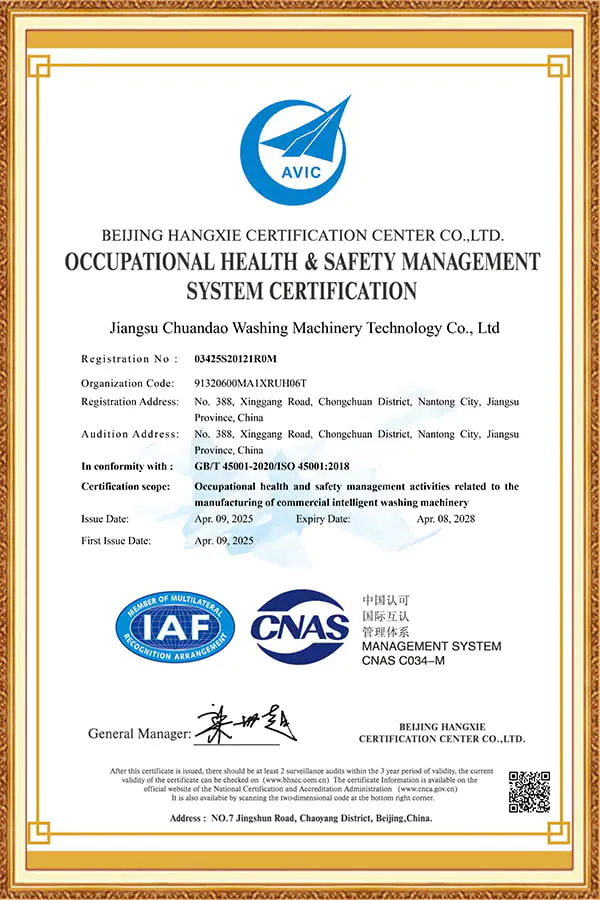

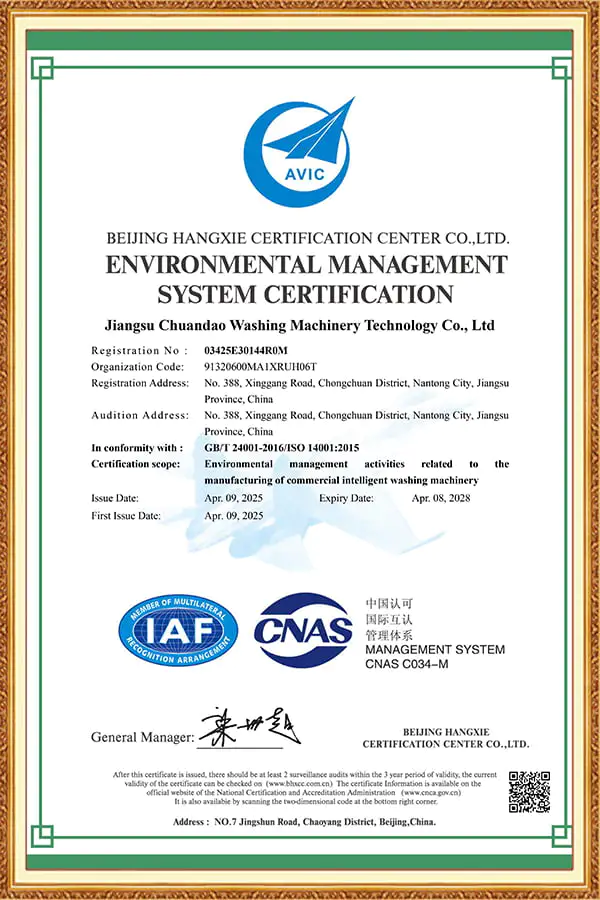

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

What is an industrial forward tilting washer and how does it work?

Definition of an Industrial Forward Tilting Washer

An industrial forward tilting washer is a large-scale laundry machine designed for handling heavy loads of textiles in industries such as healthcare, hospitality, and manufacturing. The key feature that distinguishes this washer from traditional industrial machines is its ability to tilt forward, which facilitates easier loading and unloading of laundry. This tilting mechanism reduces manual labor, improves workflow efficiency, and ensures safer handling of large volumes of wet laundry, which are otherwise heavy and difficult to move manually. It is commonly employed in environments where processing large quantities of fabrics is a daily requirement.

Design Characteristics

The design of an industrial forward tilting washer incorporates a strong drum, a robust frame, and a tilting mechanism supported by hydraulic or motorized systems. These machines are engineered for durability and continuous operation, with reinforced parts that can withstand heavy daily use. The forward tilting feature is particularly useful in minimizing strain on workers, as it allows the drum to pivot forward, making laundry accessible without the need for heavy lifting. The user interface often includes programmable controls, enabling operators to adjust cycles based on fabric type and load requirements.

Working Principle

The working principle of an industrial forward tilting washer is based on a combination of mechanical agitation, water flow, and detergent application. During the wash cycle, textiles are rotated inside the drum while water and detergents are introduced. The mechanical movement helps dislodge dirt, while chemical agents break down stains and soils. After washing, rinsing cycles remove detergent residues. The forward tilting feature becomes active at the end of the cycle, where the drum tilts forward to discharge laundry into carts or conveyors, reducing the need for manual intervention and accelerating the workflow.

Tilting Mechanism

The tilting mechanism is the defining aspect of this type of washer. It is usually controlled by a hydraulic or electric motor system that allows the drum to pivot forward at an angle sufficient for unloading. The tilt can be activated manually by operators or automatically at the end of a cycle, depending on the machine model. This feature is designed to address the physical challenges of handling heavy wet laundry, ensuring both ergonomic safety for workers and improved operational efficiency for facilities.

Loading and Unloading Efficiency

One of the primary advantages of the forward tilting washer is its impact on loading and unloading efficiency. Traditional industrial washers require manual effort to remove laundry, often involving lifting heavy loads. In contrast, the tilting design allows laundry to slide out directly into bins or carts. This minimizes downtime between cycles and reduces the risk of worker injuries. Facilities with high-volume laundry needs benefit greatly from this feature, as it streamlines daily operations and ensures faster turnaround of textiles.

Applications of Forward Tilting Washers

Forward tilting washers are used in industries where bulk laundry management is critical. Hospitals rely on them for washing bed linens, gowns, and uniforms that must meet strict hygiene standards. Hotels and resorts use them to process large volumes of bedding and towels on a daily basis. Manufacturing facilities with textile-related operations also employ these washers for cleaning fabric materials. Additionally, laundries serving institutions and large communities depend on forward tilting washers for consistent performance and time-saving benefits.

Comparison with Non-Tilting Industrial Washers

When compared to non-tilting industrial washers, forward tilting machines offer significant operational advantages. Non-tilting models require manual unloading, which increases labor demands and extends turnaround time. Forward tilting washers, on the other hand, reduce manual handling and speed up unloading. However, tilting models are typically more expensive and require additional installation space due to their pivoting mechanism. Facilities must weigh the higher initial investment against long-term benefits in efficiency and safety.

| Feature | Forward Tilting Washer | Non-Tilting Washer |

|---|---|---|

| Unloading Process | Automatic tilt-assisted unloading | Manual unloading required |

| Labor Requirements | Reduced manual handling | Higher physical effort |

| Initial Cost | Higher | Lower |

| Space Requirement | Larger due to tilt mechanism | Smaller footprint |

| Operational Efficiency | Higher efficiency, faster turnaround | Standard efficiency |

Energy and Water Consumption

Forward tilting washers are designed to optimize energy and water consumption. Many models integrate features such as programmable wash cycles, water recycling systems, and energy-efficient motors. While their overall consumption may be higher per cycle compared to smaller units, the efficiency gained by processing larger loads offsets the relative energy cost. Facilities often prioritize models with eco-friendly options to align with sustainability goals and reduce operating expenses over time.

Maintenance Requirements

Maintenance is an important aspect of operating an industrial forward tilting washer. Regular servicing of the hydraulic or electric tilting mechanism ensures reliable function over time. Additionally, cleaning the drum, checking water inlets, and inspecting seals are necessary to maintain hygiene and prevent breakdowns. These machines are designed with serviceability in mind, allowing technicians to access parts easily. Routine maintenance schedules extend the operational life of the equipment and prevent unexpected downtime in high-demand environments.

Safety Features

Safety is a critical consideration in the design of forward tilting washers. Many models include safety interlocks that prevent the drum from tilting while in motion. Emergency stop buttons and lockable control panels are often integrated to protect operators. The reduction of manual lifting also decreases the likelihood of injuries related to heavy handling. These safety enhancements make the equipment suitable for environments where worker protection and compliance with safety regulations are a priority.

Automation and Control Systems

Modern forward tilting washers often include advanced automation and control systems. Programmable logic controllers (PLC) enable operators to set specific wash cycles for different textile types, adjust water levels, and control detergent dosing. Some models are equipped with touchscreen interfaces that provide real-time data on cycle progress, energy consumption, and machine status. Automation not only increases consistency in washing results but also reduces operator errors and simplifies workflow management.

Installation Requirements

Installing an industrial forward tilting washer requires careful planning. Due to their size and tilting mechanism, these machines need sufficient floor space and structural support. Access to high-capacity water inlets, drainage systems, and electrical supply is necessary. Facilities must also ensure proper ventilation and space for maintenance access. Professional installation is recommended to ensure the machine operates safely and efficiently. These requirements differ significantly from smaller, non-industrial washers used in domestic or small commercial settings.

Operational Costs

The operational costs of forward tilting washers include energy, water, detergents, and maintenance expenses. While initial investment is higher than standard industrial washers, the reduced labor requirements and faster turnaround times often lead to cost savings in the long term. Facilities processing high volumes of laundry find that the efficiency gains offset the additional costs associated with the advanced tilting design. Budget planning should consider both immediate expenses and long-term savings.

Advantages of Forward Tilting Design

The forward tilting design provides clear advantages in terms of ergonomics, workflow efficiency, and safety. By eliminating the need for workers to manually lift heavy loads of wet laundry, it reduces strain and the risk of injury. It also accelerates unloading, enabling facilities to complete more cycles in less time. These advantages contribute to overall productivity and worker well-being in industries where laundry operations play a crucial role in daily functioning.

Limitations of Forward Tilting Washers

Despite their many advantages, forward tilting washers have certain limitations. They are generally more expensive than traditional models, making them less accessible for smaller businesses. The tilting mechanism adds complexity, which can lead to higher maintenance requirements compared to simpler machines. Additionally, they require more installation space, which may not be available in all facilities. Organizations must evaluate these limitations in the context of their operational needs and resources.

Future Trends in Industrial Washers

The future of industrial forward tilting washers lies in further integration of automation, energy efficiency, and smart technology. Upcoming models are likely to include advanced sensors for water and energy optimization, remote monitoring capabilities, and predictive maintenance tools. These advancements will enhance machine reliability and sustainability, ensuring that industrial laundry operations continue to meet the evolving demands of different industries. The forward tilting mechanism will remain a core design feature, supporting ergonomic and operational improvements in laundry management.

What is the typical water and energy consumption per wash cycle for an industrial forward tilting washer?

Definition of Industrial Forward Tilting Washer

An industrial forward tilting washer is a type of large-scale washing machine primarily used in commercial and industrial laundry facilities. It is designed with a forward tilting drum mechanism that allows the washer to tilt outward at the front, making it easier to unload heavy batches of laundry. This type of washer is commonly used in hospitals, hotels, textile plants, and other facilities where large volumes of linens, uniforms, or fabric items need to be cleaned efficiently. Unlike domestic washers, it is built for continuous operation and higher durability while also incorporating advanced systems for water and energy optimization.

Importance of Understanding Consumption Metrics

Knowing the typical water and energy consumption per wash cycle for an industrial forward tilting washer is critical for facility managers and operators. These machines often handle hundreds of kilograms of laundry per load, meaning their impact on utility costs and resource efficiency is significant. By analyzing consumption metrics, businesses can forecast operating expenses, identify areas for improvement, and ensure that environmental sustainability goals are being met. Additionally, understanding these values helps compare different models and manufacturers to select equipment that balances performance with long-term operating efficiency.

Water Consumption Per Wash Cycle

Water consumption in an industrial forward tilting washer depends on load size, washing program, and machine capacity. On average, such machines consume between 6 to 12 liters of water per kilogram of dry laundry. For example, a 100 kg load capacity machine might use approximately 800 to 1200 liters of water per cycle, depending on the wash program. Some modern models are equipped with water recycling systems that can reduce overall water use by reusing rinse water in subsequent cycles. These measures not only lower operational costs but also contribute to more sustainable laundry practices in industries where water usage is a major concern.

Energy Consumption Per Wash Cycle

The energy consumption of an industrial forward tilting washer is typically measured in kilowatt-hours (kWh) per cycle. Energy is required to heat the water, power the drum motor, and operate the control systems. On average, an industrial washer may consume between 8 to 15 kWh per 100 kg load, depending on wash temperature, cycle duration, and the presence of features like water recycling or heat recovery systems. For example, washing at higher temperatures, such as 90°C, will require more energy compared to low-temperature wash cycles at 40°C. Energy-efficient models are designed to minimize heating losses and optimize drum motion to achieve thorough cleaning with less energy input.

Comparison of Water and Energy Usage

To better illustrate the relationship between water and energy usage, the following table provides a typical consumption range for industrial forward tilting washers compared to smaller commercial machines.

| Machine Type | Capacity (kg) | Water Consumption (liters per cycle) | Energy Consumption (kWh per cycle) |

|---|---|---|---|

| Commercial Washer | 25 - 40 | 200 - 350 | 2 - 5 |

| Industrial Forward Tilting Washer | 100 - 200 | 800 - 1800 | 8 - 15 |

| Advanced Industrial Washer with Recycling | 100 - 200 | 600 - 1200 | 7 - 12 |

Factors Influencing Consumption

Several factors influence the actual water and energy usage of an industrial forward tilting washer. Load size plays a major role, as underloading the washer leads to inefficient use of resources, while overloading may reduce wash quality and extend cycle times. The type of textiles being washed also matters; heavily soiled fabrics may require longer wash cycles with additional rinses, increasing both water and energy use. The wash temperature directly affects energy consumption, with hot washes demanding significantly more electricity for water heating. Additionally, the presence of automation features such as water reuse systems, load sensing technology, and programmable wash cycles can alter consumption levels considerably.

Technological Advances in Reducing Consumption

Modern industrial forward tilting washers are increasingly designed with technology that reduces resource consumption. Water recycling systems capture rinse water and reuse it for the next cycle, while energy recovery systems utilize waste heat from discharged water to preheat incoming water. Variable frequency drives (VFDs) are also employed to control drum speed more efficiently, minimizing energy demand. Programmable microprocessors allow users to fine-tune wash cycles to the exact requirements of the laundry load, avoiding unnecessary water and energy usage. These innovations not only reduce operational costs but also align with environmental sustainability objectives across industries.

Cost Implications of Consumption

The water and energy consumption of industrial forward tilting washers has direct cost implications for facilities. For example, if a 100 kg washer uses 1000 liters of water and 12 kWh of electricity per cycle, operating it five times daily would result in 5000 liters of water and 60 kWh of energy consumption. Over a year, this translates to millions of liters of water and tens of thousands of kWh in energy usage. Therefore, facilities must evaluate long-term operating costs when selecting machines and consider investments in models with resource-saving features, as these can lead to substantial financial savings in the long run.

Environmental Considerations

Beyond cost, water and energy consumption of industrial washers have environmental implications. High water usage can place stress on local water supplies, particularly in regions where water scarcity is an issue. Energy usage contributes to carbon emissions if sourced from fossil fuels. By adopting washers with lower consumption rates and implementing operational strategies like using lower temperature cycles when possible, businesses can reduce their environmental footprint. Additionally, integrating renewable energy sources, such as solar or biomass heating for water, can further minimize the environmental impact of operating industrial forward tilting washers.

Operational Practices to Improve Efficiency

While machine design plays a significant role in determining consumption, operator practices are equally important. Training staff to load machines properly, select the right wash cycles, and perform routine maintenance ensures optimal efficiency. Regular maintenance prevents scale buildup in heating elements, which can otherwise increase energy demand. Proper management of wash schedules also helps by avoiding frequent small loads, which waste resources compared to full-capacity washes. Facilities can implement monitoring systems that track water and energy usage per cycle, allowing operators to identify inefficiencies and take corrective action promptly.

Future Trends in Industrial Washer Efficiency

The future of industrial forward tilting washers is likely to see further reductions in water and energy consumption due to technological advancements. Smart washers with IoT-enabled systems will provide real-time monitoring of consumption metrics, enabling predictive maintenance and optimized performance. Artificial intelligence may play a role in automatically adjusting wash cycles based on fabric type and soil level, ensuring resources are used only where necessary. Furthermore, increased emphasis on sustainability regulations is expected to drive manufacturers toward designs that further minimize consumption without compromising wash performance.

English

English русский

русский Español

Español Deutsch

Deutsch