Product Series

Commercial Washer-Extractor Manufacturers

Commercial Washers: Kingstar softmount commercial coin-operated washers are available in 15kg, 20kg, and 25kg capacities. The unique bottom-suspension design allows installation on any floor without requiring a dedicated foundation. All water-contact components – including the inner drum, outer cylinder, and associated parts – are constructed from 304 stainless steel. This eliminates rust formation and prevents any compromise to wash quality. Critical components such as electrical elements and bearings utilize high-quality imported brands. The main transmission employs a robust triple-bearing design, ensuring smooth operation and extended service life.

Operation is simplified through a 7-inch touchscreen interface capable of storing 30 customizable wash programs. Users select the appropriate program for one-touch startup. Multiple payment options are supported: coin operation, QR code scanning, card payment (credit/debit or prepaid cards), and central payment systems. This versatility makes the units suitable for laundromats, apartment buildings, schools, hospitals, and various other settings. Multilingual support (including English, Japanese, and French) caters to diverse user groups, enhancing convenience while offering unprecedented flexibility and reduced operational costs for service providers.

A high dewatering rate significantly reduces subsequent drying time and costs. The main motor, custom-manufactured by a listed company, delivers exceptional performance. With a 300G G-force factor, it effectively minimizes residual moisture in garments, lowering heat consumption during drying and increasing profitability for operators.

Safety features include an electronic door lock that only releases after the drum comes to a complete stop, protecting users. The coin control box incorporates anti-pry design to safeguard the service provider's revenue.

Commercial Dryers: Kingstar commercial dryers offer multiple configurations: single-unit coin-operated dryers, stackable dryers, and stackable washer-dryer combos (washer below, dryer above). This range accommodates different space constraints and laundry room layouts.

The 304 stainless steel drum features a smooth surface to minimize fabric wear and extend equipment longevity. Touchscreen controls provide intuitive operation with preloaded automatic drying programs. Simply select the program matching the fabric type for one-touch drying initiation. The drum adheres to a 1:20 load ratio design; its generous volume allows clothes to tumble freely, enhancing drying efficiency and reducing wrinkles.

An intelligent hot/cold air circulation system optimizes energy use and fabric care. The system sets upper and lower temperature thresholds: when the drum reaches the upper limit, it stops blowing hot air and introduces cool air; when it cools to the lower limit, hot air resumes. This cycle reduces energy consumption while preventing heat damage to fabrics. A specially treated lint filter efficiently captures lint, further boosting drying performance.

Payment options mirror the washers (coin, card, QR code, central system), and multilingual interfaces ensure user-friendliness. The streamlined operation significantly enhances the user experience.

Kingstar commercial laundry equipment is designed, engineered, and manufactured by CLM, China’s leading commercial laundry equipment brand with 25 years of industrial expertise. As AI technology advances, coin-operated machines are evolving towards greater intelligence. Kingstar commercial washers and dryers are widely deployed in laundromats, campus laundry facilities, hotel/apartment self-service laundries, and more. They provide diverse populations with fast, convenient laundry services, substantially improving quality of life.

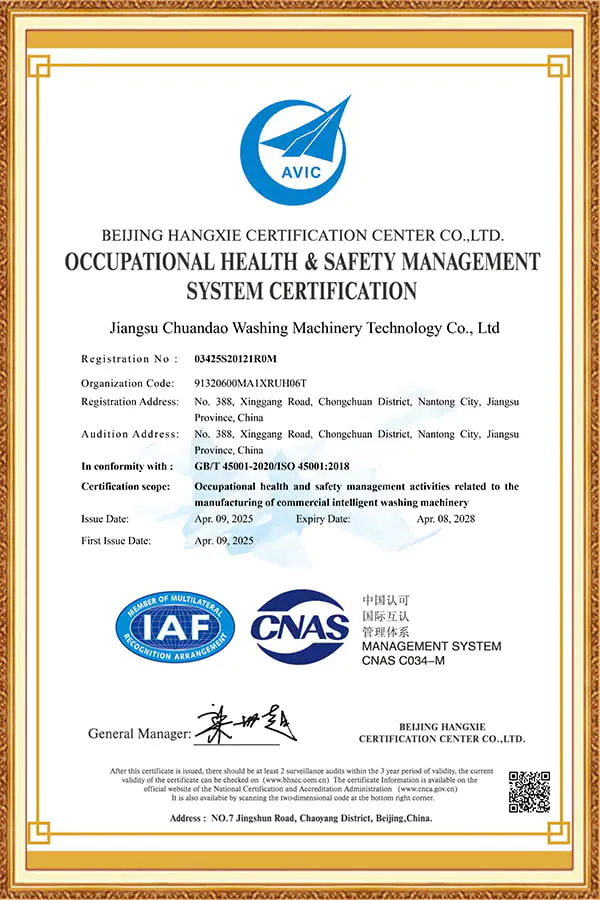

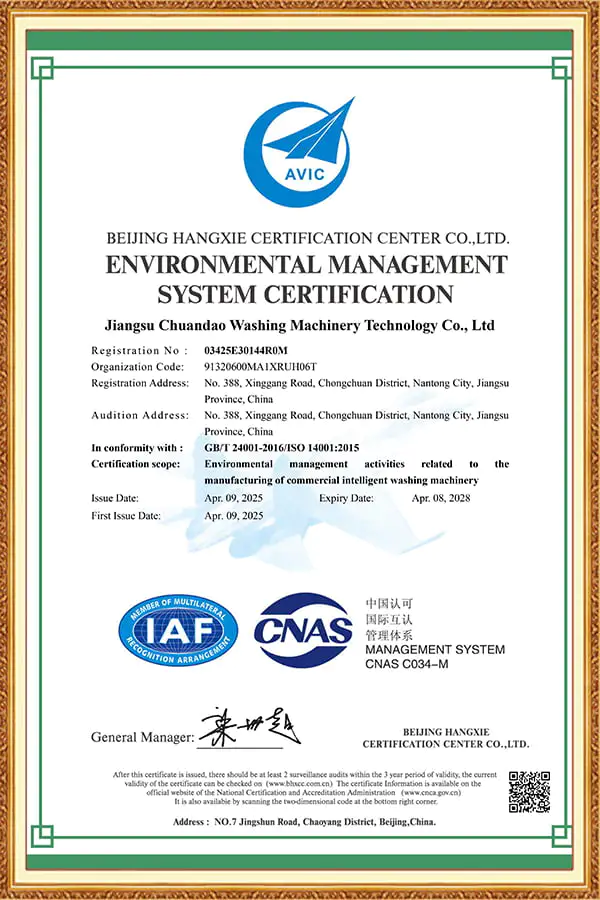

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

NEWS

2.Soft Mount Washers: Redefining Efficiency and Performance

3.The Future of Wet Washing Machines: Technology and Sustainability

English

English русский

русский Español

Español Deutsch

Deutsch