Coin-Operated Stacked Washer Dryer - Hardmount(12/15/20kg)

Kingstar’s coin-operated commercial washer dryers are built to deliver superior efficiency, long-term durability, and user-friendly operation. With a range of customizable options, they are well-suited for laundromats, apartment communities, and hotel facilities. Designed for consistent performance and minimal maintenance, these machines are a dependable choice for professional laundry operations. Get in touch with us to explore solutions tailored to your needs.

-

Laundry

-

Dry cleaner

-

Self-service

laundry

- 12kg

- 15kg

- 20kg

(86)+86-13917089379

-

① Space-Saving Stacked Design

The Kingstar coin-operated stacked washer-dryer reduces floor space usage by up to 50%compared to standalone units, maximizing ROI in space-constrained laundry rooms.ldeal for self-service laundromats, schools, apartments, hotels, and more. -

② Intelligent Control System

Equipped with a 7-inch full-color touchscreen, the system supports over 30 languages and guides users in customizing wash-dry cycles based on fabric types and load characteristics—offering a user-friendly, intuitive experience. -

③ Durable Inner Drum Design

The inner drum is made from high-grade 304 stainless steel, ensuring long-term corrosion resistance. This design prevents rust-related failures and protects both garments and users from damage or safety hazards. -

④ Multiple Payment Methods

Offering convenience to users and enhanced operational flexibility for laundry service providers, while helping reduce overhead costs. -

⑤ Intelligent Weighing System

The intelligent weighing function automatically adjusts water usage based on the actual load, helping minimize energy and detergent consumption while ensuring optimal washing results. -

⑥ High-Efficiency Dehydration

Featuring a spin speed of 850 rpm and a 300G extraction force, the washer efficiently reduces residual moisture, which leads to shorter drying cycles and lower operational energy costs. -

⑦ Efficient Lint Filtration

The specially treated lint filter effectively traps lint particles during the drying process, improving airflow and enhancing overall drying efficiency. -

⑧ Advanced Energy-Saving Technology

Engineered to meet stringent commercial standards for water and energy efficiency, the system helps reduce utility costs without compromising performance. A high-efficiency heater, paired with an optimized air duct system and hot/cold air circulation, ensures rapid drying with minimal energy consumption. -

⑨ Tamper-Resistant Security Design

A robust anti-pry coin control box protects revenue from theft or tampering, offering laundry operators peace of mind and enhanced property security.

-

Simple operation

Simple operation -

Intelligentize

Intelligentize -

Humanized design

Humanized design -

High quality

High quality

|

Specification Model |

SWD-3012C(Hardmount) |

SWD-3015C(Hardmount) |

SWD-3020C(Hardmount) |

|

Operating Voltage(V/P/Hz) |

380/3/50 |

380/3/50 |

380/3/50 |

|

Washing Capacity(kg) |

5~12 |

5~15 |

8~20 |

|

Drum Volume(L) |

120 |

150 |

200 |

|

Washing/Spinning Speed(rpm) |

30-740 |

30-740 |

30-690 |

|

Transmission Power(kw) |

1.5 |

1.5 |

2.2 |

|

Electrical Heating Power(kw) |

12 |

12 |

12 |

|

Noise(db) |

≤70 |

≤70 |

≤70 |

|

Dehydration Factor(G) |

200 |

200 |

200 |

|

Automatic Dosing Ports (ways) |

8 |

8 |

8 |

|

Inlet Water Pressure(Mpa) |

0.2-0.4 |

0.2-0.4 |

0.2-0.4 |

|

Inlet Pipe Diameter(mm) |

DN20 |

DN20 |

DN20 |

|

Hot Water Pipe Diameter(mm) |

DN20 |

DN20 |

DN20 |

|

Drain Pipe Diameter(mm) |

DN65 |

DN65 |

DN65 |

|

Washing Drum Diameter×Depth(mm) |

650×372 |

650×465 |

650×465 |

|

Drying Drum Diameter×Depth(mm) |

750×560 |

757×685 |

850×640 |

|

Drying Drum Load Ratio(L) |

240 |

300 |

360 |

|

Drying Drum Load Ratio |

1:20 |

1:20 |

1:18 |

|

Main Motor Power(KW) |

0.20 |

0.20 |

0.37 |

|

Fan Motor Power(KW) |

0.20 |

0.20 |

0.55 |

|

Heating Method |

Electric/Gas Heating |

Electric/Gas Heating |

Electric/Gas Heating |

|

Rated Voltage(v) |

380 |

380 |

380 |

|

Heater Power(KW) |

9 |

13.5 |

18 |

|

Width(mm) |

800 |

800 |

890 |

|

Depth(mm) |

1110 |

1210 |

1180 |

|

Height(mm) |

1980 |

1980 |

2140 |

|

Total Weight(kg) |

410 |

450 |

540 |

About us

Craftsman spirit, excellence, quality products are the bridge to the world!

Kingstar brand is the crown jewel of CLM in the commercial laundry industry. For over 20 years, we carefully selected and updated our material suppliers and technology. We aim to be the best in the industry internationally and offer more to clients who rely on us for their business.

We hold the leading status in the laundry manufacturing industry in China after 25+ years of experience.

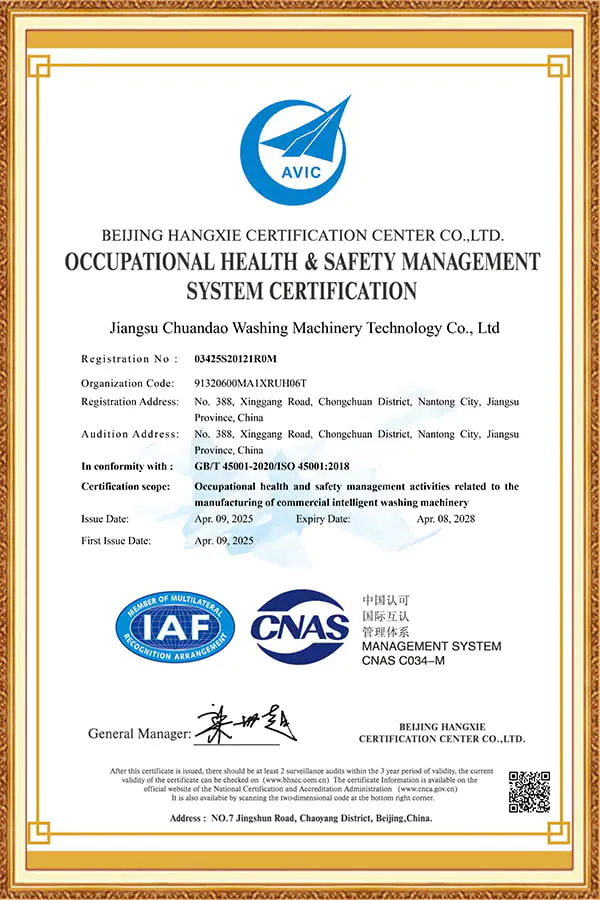

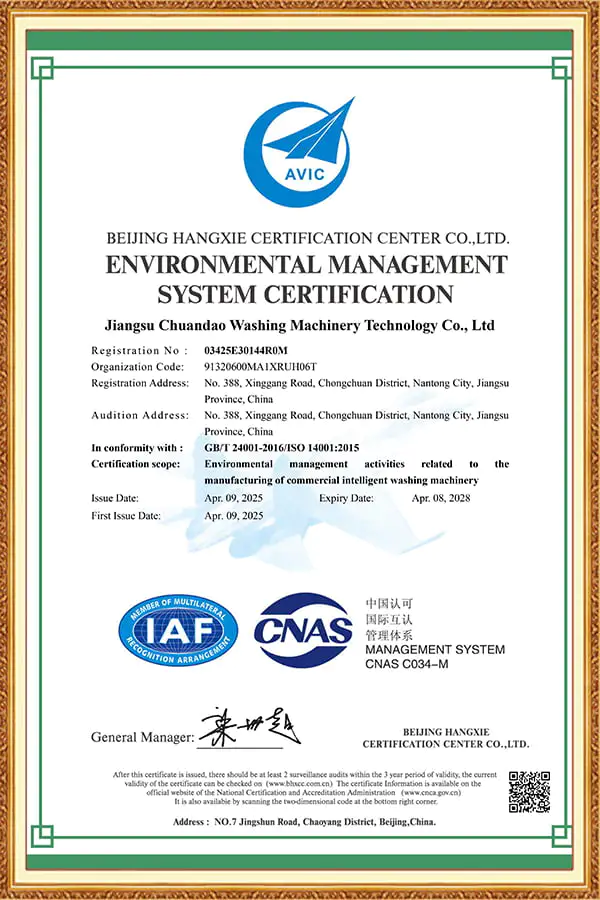

Honor & Qualification

Choose comes from trust, and cooperation

comes from honesty.

NEWS

What is a coin-operated stacked washer dryer – hardmount and how does it work?

Definition of a Coin-Operated Stacked Washer Dryer – Hardmount

A coin-operated stacked washer dryer – hardmount is a type of commercial laundry equipment that combines both a washer and a dryer in a vertical configuration. It is designed with a hardmount structure, meaning the machine must be bolted directly to a reinforced concrete floor. This requirement allows the machine to handle the high-speed extraction forces generated during the spin cycle. The stacked design optimizes space by allowing two machines to occupy the footprint of one, making it a common choice in laundromats, multi-housing complexes, and institutional laundry facilities. The coin-operated feature provides a direct revenue system by enabling customers to pay per wash or dry cycle.

Structural Features of Hardmount Design

The hardmount design differentiates this equipment from softmount models. By anchoring the unit to a solid foundation, the washer can reach high extraction speeds without excessive vibration. This improves water removal efficiency during spin cycles and reduces drying times. The hardmount construction typically includes heavy-duty bearings, reinforced frames, and shock-absorbing components. These structural features contribute to long-term durability in demanding environments. However, installation requires professional preparation, including reinforced flooring, to ensure stability and proper operation.

Stacked Washer Dryer Configuration

In a coin-operated stacked washer dryer – hardmount, the washer is usually located at the bottom and the dryer at the top. This arrangement makes it convenient for users to load wet clothes directly from the washer to the dryer without needing additional space between units. The vertical design maximizes efficiency in environments where floor space is limited. Despite the compact footprint, each machine operates independently, meaning customers can use either the washer, the dryer, or both at the same time depending on their needs. This configuration provides operational flexibility while maintaining space efficiency.

Coin-Operated Payment Mechanism

The inclusion of a coin payment system is a defining feature of this equipment. Customers insert coins to activate the wash or dry cycle, with the price determined by the facility operator. In modern models, the coin system is often complemented by card readers or mobile payment options, offering greater flexibility to users. The payment system is integrated with the machine’s control panel, ensuring that a cycle begins only after payment is made. For operators, coin-operated systems provide a reliable revenue stream, while secure cash boxes and locking mechanisms prevent tampering.

Operation of the Washer Unit

The washer unit functions like other front-loading commercial washers. Users load clothes into the drum, select the desired wash cycle, and initiate operation after payment. Water is introduced into the drum along with detergent, and the drum rotates at controlled speeds to agitate fabrics. During the spin cycle, the drum accelerates to high speeds, extracting water from fabrics through centrifugal force. The hardmount foundation ensures stability during this process, enabling efficient water removal that reduces the drying time in the companion dryer.

Operation of the Dryer Unit

The dryer component, located above the washer, operates using heated air circulated through the drum. Users can load wet clothes from the washer directly into the dryer. After selecting a drying cycle and paying through the coin system, the dryer begins operation. Air is heated using either electricity or gas, depending on the model, and circulated through the drum to evaporate moisture. Exhaust systems then remove the humid air, ensuring efficient drying. The dryer unit works independently, so multiple users can run different cycles simultaneously if needed.

Energy and Water Consumption

Hardmount stacked washer dryers are designed for efficiency, balancing resource use with performance. The washer typically consumes less water per cycle compared to residential machines due to optimized drum design and programmable wash cycles. High extraction speeds reduce the amount of water left in fabrics, which decreases the energy required for drying. The dryer consumes energy based on heating source and load size, with gas models generally being more efficient in terms of operational cost. Operators often monitor resource consumption to manage operational expenses, especially in high-volume laundromats.

Comparison Between Hardmount and Softmount Stacked Units

Hardmount stacked units differ significantly from softmount alternatives. While both share the same stacked configuration, their installation and operating requirements vary. Hardmount machines require reinforced flooring and bolting, while softmount units use suspension systems and can be installed on standard floors. The following table highlights the key differences between the two designs.

| Feature | Hardmount Stacked Washer Dryer | Softmount Stacked Washer Dryer |

|---|---|---|

| Installation | Requires reinforced concrete floor, bolted down | Can be installed on most floors, suspension system |

| Vibration Control | Controlled through floor anchoring | Suspension system absorbs vibration |

| Extraction Speed | Higher due to stable mounting | Moderate, limited by suspension system |

| Initial Setup Cost | Higher due to foundation requirements | Lower, simpler installation |

| Durability | Suited for heavy-duty, frequent use | Suited for flexible installation environments |

User Experience

For customers, the stacked washer dryer – hardmount provides convenience and reliability. The vertical design minimizes space requirements, making it easier to operate in crowded laundromats or small laundry rooms. The simple coin-operated interface is user-friendly, and modern models often incorporate clear cycle instructions and digital displays. Customers benefit from faster drying due to efficient water extraction during the wash cycle. Accessibility is considered in design, with washer doors typically placed at a comfortable height and dryer controls located within reach.

Maintenance Considerations

Regular maintenance is essential to keep coin-operated stacked washer dryers functioning effectively. Maintenance typically includes inspecting hoses and connections, cleaning lint traps in the dryer, checking the coin mechanism for jams, and lubricating moving parts. Since hardmount models are bolted to the floor, service access panels are provided to facilitate repairs without relocating the machine. Some models include diagnostic systems that identify operational issues, simplifying troubleshooting for technicians. Preventive maintenance schedules reduce downtime and extend the service life of the equipment.

Revenue and Business Applications

Coin-operated stacked washer dryers – hardmount are popular in laundromats, multi-housing units, student dormitories, hotels, and military or correctional facilities. The coin mechanism ensures a steady revenue stream, while the stacked design maximizes machine capacity in limited spaces. Operators can adjust pricing per cycle to match local market conditions, utility costs, and business models. The durability and reliability of these machines reduce the need for frequent replacements, making them a practical long-term investment for commercial operators.

Technological Enhancements

Modern versions of coin-operated stacked washer dryers include advanced technology to improve performance and usability. Programmable electronic controls allow operators to customize cycle settings such as water temperature, wash time, and spin speed. Some machines integrate digital payment systems alongside traditional coin operation, offering contactless card or mobile payment options. Connectivity features may allow operators to remotely monitor machine usage, collect revenue data, and receive maintenance alerts. These advancements enhance both user experience and operational efficiency.

Advantages in Space-Constrained Environments

The stacked design offers clear advantages in environments where floor space is limited. By placing the dryer directly above the washer, operators effectively double machine capacity without requiring additional footprint. This makes them particularly useful in urban laundromats, apartment complexes, and facilities where available space is restricted. The ability to provide both washing and drying functions in one unit also improves workflow efficiency for users, as they can transfer clothes quickly between cycles without moving to another machine.

Safety Features

Safety is a key consideration in the design of coin-operated stacked washer dryers. Hardmount stability prevents excessive movement during operation, reducing the risk of tipping or vibration-related damage. Machines are equipped with door locks that prevent opening during active cycles, protecting users from potential hazards. Overheating sensors in the dryer and water overflow controls in the washer add further layers of protection. These features ensure safe operation in busy commercial environments where machines are used frequently throughout the day.

Return on Investment

For operators, the investment in coin-operated stacked washer dryers – hardmount is justified by their long-term reliability, efficient use of space, and consistent revenue generation. Although installation requires higher upfront costs due to reinforced flooring, the durability and high extraction efficiency contribute to reduced utility costs over time. The combination of steady customer usage, efficient performance, and robust construction provides a reliable return on investment. When properly maintained, these machines deliver years of service, reducing the need for frequent replacements.

How can a coin-operated stacked washer dryer minimize vibration during operation?

Understanding Vibration in Coin-Operated Stacked Washer Dryers

Coin-operated stacked washer dryers are widely used in commercial and semi-commercial laundry environments such as laundromats, apartment complexes, and institutional facilities. During operation, vibration naturally occurs as a result of drum rotation, load imbalance, and high-speed extraction. While some vibration is inevitable, excessive vibration can cause structural wear, increase noise, and affect user comfort. To address these issues, manufacturers integrate multiple design features and installation requirements aimed at minimizing vibration while ensuring efficient performance. Understanding the causes of vibration and the strategies used to reduce it provides insight into the overall design of these machines.

The Role of Hardmount and Softmount Designs in Vibration Control

Coin-operated stacked washer dryers are available in both hardmount and softmount designs, and the method of vibration control varies between the two. Hardmount machines are bolted directly to reinforced concrete floors, using the rigidity of the foundation to stabilize the machine during high-speed extraction. Softmount machines, by contrast, use suspension systems with springs and shock absorbers to isolate vibration. In stacked units, this distinction becomes critical, as two machines are combined in one vertical system. Both approaches aim to reduce transmitted vibration to surrounding structures, though they achieve this through different engineering methods. The choice between hardmount and softmount depends on installation environment, space, and budget considerations.

Importance of Proper Installation

Installation plays a central role in minimizing vibration in coin-operated stacked washer dryers. For hardmount models, reinforced concrete floors with adequate thickness are required to support anchoring bolts. If installed on insufficient flooring, even the most advanced vibration control systems will be compromised. For softmount units, ensuring correct leveling is essential, as uneven placement can cause load imbalances and increased vibration. Professional installation ensures that all bolts, suspension systems, and alignment features are properly secured, providing the machine with a stable foundation. Without proper installation, vibration can be magnified, leading to reduced equipment lifespan and higher maintenance needs.

Load Distribution and Balancing

One of the most common causes of vibration in washers is unbalanced loads. In a coin-operated stacked washer dryer, users may overload one side of the drum or wash heavy items that cluster together. To minimize this, modern washers include automatic load balancing systems. Sensors detect imbalance during spin cycles and adjust drum speed accordingly. In some cases, the machine redistributes the load by tumbling before resuming extraction. Educating users through posted guidelines also helps minimize improper loading. By maintaining balanced loads, vibration levels are significantly reduced, ensuring smoother operation and protecting internal components.

Shock Absorption Systems

Softmount stacked washer dryers rely heavily on suspension systems that combine springs, dampers, and shock absorbers. These components isolate drum movement from the external frame, absorbing forces generated during spin cycles. High-quality suspension reduces vibration transmission to the floor and surrounding structures. In stacked designs, where stability is even more critical, shock absorption ensures that vibration from the washer does not affect the dryer above. Over time, these components require inspection and replacement to maintain effectiveness. Properly functioning suspension systems are a key factor in minimizing vibration in softmount stacked washer dryers.

High-Speed Extraction and Drum Design

The drum and motor design of a coin-operated stacked washer dryer also influences vibration control. Drums engineered with balanced weight distribution reduce the risk of uneven rotation. High-speed extraction removes water efficiently, but without proper balancing mechanisms, it can increase vibration. To counter this, manufacturers design drums with perforations and optimized geometry that evenly distribute fabrics during spin cycles. Drive systems with variable frequency motors allow gradual acceleration, reducing sudden jolts that could otherwise cause imbalance. These features combine to enhance stability while maintaining efficient washing and drying performance.

Base and Frame Reinforcement

The overall structure of a stacked washer dryer must withstand repeated cycles of motion and vibration. Reinforced frames and durable base plates add rigidity, preventing excessive movement. In hardmount designs, heavy-duty anchoring combined with frame reinforcement ensures that vibration forces are distributed evenly. For softmount designs, reinforced bases support suspension systems, improving overall durability. The stacked configuration requires special attention to frame stability, as the dryer is mounted above the washer. Reinforced frames reduce flexing and resonance, which are common contributors to vibration-related issues.

Routine Maintenance and Inspection

Regular maintenance is another important factor in reducing vibration. Worn suspension components, loose bolts, or deteriorated shock absorbers can amplify vibration over time. Coin mechanisms, lint traps, and water hoses should also be inspected regularly, as secondary issues may affect machine stability. Technicians often perform vibration diagnostics to detect imbalances or worn parts early. By addressing small issues before they develop into larger problems, maintenance extends the service life of the equipment and ensures smoother operation. Preventive maintenance is especially important in commercial environments, where machines are subjected to heavy daily use.

Comparison of Vibration Reduction Methods

Different vibration reduction strategies are employed depending on the design and installation of the coin-operated stacked washer dryer. The following table summarizes key approaches and their impact on performance.

| Vibration Control Method | Application | Impact |

|---|---|---|

| Floor Anchoring | Hardmount washers | Provides stability by securing unit to reinforced concrete |

| Suspension System | Softmount washers | Absorbs shock and isolates vibration from the floor |

| Load Balancing Sensors | Both hardmount and softmount | Detects imbalance and redistributes load during spin |

| Reinforced Frame | Both designs | Prevents flexing and resonance, improving stability |

| Variable Frequency Drive | Advanced models | Controls acceleration to reduce sudden jolts |

User Education and Guidelines

Users play an active role in minimizing vibration. Coin-operated machines are often used by a wide range of customers with varying knowledge of proper laundry practices. Posting clear instructions, such as avoiding overloading, distributing items evenly, and not mixing heavy and light fabrics, can reduce vibration during operation. Many laundromats provide signage or digital displays that guide users through loading recommendations. By encouraging proper loading practices, operators reduce wear on machines and provide a better experience for all users.

Technological Enhancements in Vibration Control

Modern stacked washer dryers incorporate advanced technologies to further minimize vibration. In addition to load balancing sensors, some machines use microprocessor controls to continuously monitor drum movement. Intelligent algorithms adjust speed and direction to maintain balance. Connectivity features allow operators to remotely track machine performance, including vibration data, which helps identify emerging issues. These enhancements improve operational stability while reducing noise levels, contributing to a more comfortable laundry environment. Technology-driven vibration control also reduces maintenance costs by preventing excessive wear on components.

Impact of Vibration Control on Durability

Effective vibration control not only improves user experience but also extends the service life of stacked washer dryers. Excessive vibration places strain on bearings, seals, and electrical connections, leading to premature failures. By minimizing vibration, these stresses are reduced, allowing machines to operate reliably over extended periods. For operators, this translates into fewer service interruptions, lower repair costs, and improved return on investment. The durability benefits of vibration control are particularly valuable in commercial settings where equipment is used continuously.

Noise Reduction Through Vibration Management

One of the side benefits of minimizing vibration is reduced noise. Vibrating drums and frames often produce loud operational sounds that can disturb users. By stabilizing the washer and dryer during operation, vibration control reduces resonance and rattling. In environments such as multi-housing units or dormitories, noise reduction contributes to overall user satisfaction. Some models also incorporate sound-dampening materials alongside vibration control measures, further enhancing the laundry experience.

Conclusion on Vibration Management Practices

Coin-operated stacked washer dryers use a combination of engineering design, installation practices, user education, and technology to minimize vibration. Anchoring systems, suspension designs, reinforced frames, and balancing sensors all work together to stabilize operation. Proper installation and maintenance further enhance vibration control, ensuring reliable performance in demanding commercial environments. By addressing vibration effectively, operators extend the life of their equipment, reduce maintenance costs, and provide users with a more efficient and comfortable laundry experience.

English

English русский

русский Español

Español Deutsch

Deutsch